Prime-MDx

Diagnostic Equipment Project

The world of diagnostics has always been about innovating its processes, making its results reliable, especially during and after the pandemic when it experienced an unprecedented acceleration.

The world of diagnostics has always been about innovating its processes, making its results reliable, especially during and after the pandemic when it experienced an unprecedented acceleration.

The goal that Menarini Diagnostics has set when thinking about the development of the Prime-MDx is that of processing many samples in a short period of time, thus improving the workflow in molecular diagnostics and maximizing the reliability of the tests.

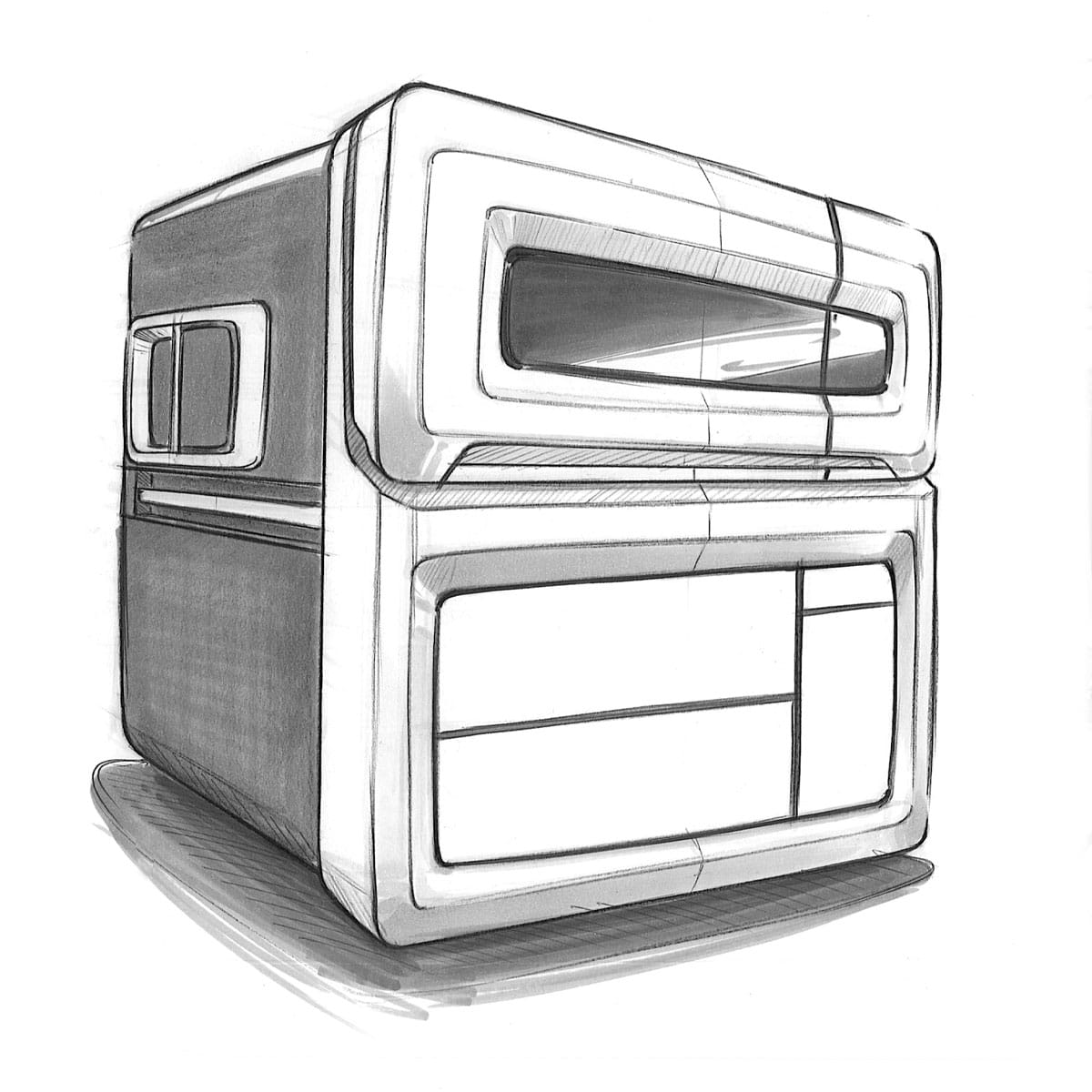

The Prime-MDx design was entrusted to MM Design, with the ambitious goal of improving the usability and intuitiveness of functions, while having a modern, unique, and captivating design. Prime-MDx has thus become the all-in-one, fully-automated solution, from sample to result, which is designed to simplify laboratory workflows for samples to be subjected to molecular biology analysis with a PCR (Polymerase Chain Reaction) technique in real-time with efficiency, flexibility, and ease of use.

The architecture of the machine in particular is divided into two areas of interaction: the left side, which is accessed via a door operated by vertical slides, allowing the operator to have the entire compartment in view and dedicated to inserting test tubes, reagents, and other accessories; and the right side, with its book-opening door, which allows access to the PCR instrument. The upper section has a frame which incorporates the doors, while the drawers for storing reagents and other items is located in the lower section, as well as the workstation for a computer, which acts as the Management System of the instrument.

The design has also taken it upon itself to find solutions for the handling of the equipment, and for this reason, special wheels have been used on which the considerable weight of the entire machine is unloaded and, once installed, are disengaged with special jacks. For handling, side handles recessed into the bodywork have been designed to contain the overall volume. The doors are equipped with special darkened glass and allow inspection inside the compartment, while the monitor and capacitive display in the right area has been integrated into the door with a book opening to ensure greater linearity, while also facilitating ordinary and extraordinary maintenance.

The design concept provides for the integration of many functions into a single body that are connected to each other, but which previously existed separately or were not provided for at all. This is a unique and unmistakable design represented by a generously sized frame that cradles the upper section with the lower one and acts as a proscenium for the doors and drawers. The use of a Baydur for the front areas and painted sheet metal for the sides and rear has enabled cost containment and an optimal coupling for these large surfaces.

The project was the result of a very assiduous collaboration between Menarini Diagnostics as client and project managers, MM Design for the design and development of the aesthetic and ergonomic parts, Masmec for the realization of all the technical parts of the machine both HW and SW, and S4Technology for making molds and equipment for plastic parts.

Contact us to have more information about our projects, our ways of working and on the events that we orgaize and how we can collaborate with your business.