S1 P4, The new Corporate Design for Salvagnini

Europe, as part of the model of Industry 4.0, has been primary in the adoption of technologies, including the stand-out (based on a total number of plants) which is sheet metal processing. Many future products will be made with this material, which will reduce investment costs by keeping the price for molds to a minimum, as a result of a decrease in pieces made, as well as frequently updating the final products. The creation of such combined systems improves workflow, reduces processing times and makes the use of these products extremely flexible.

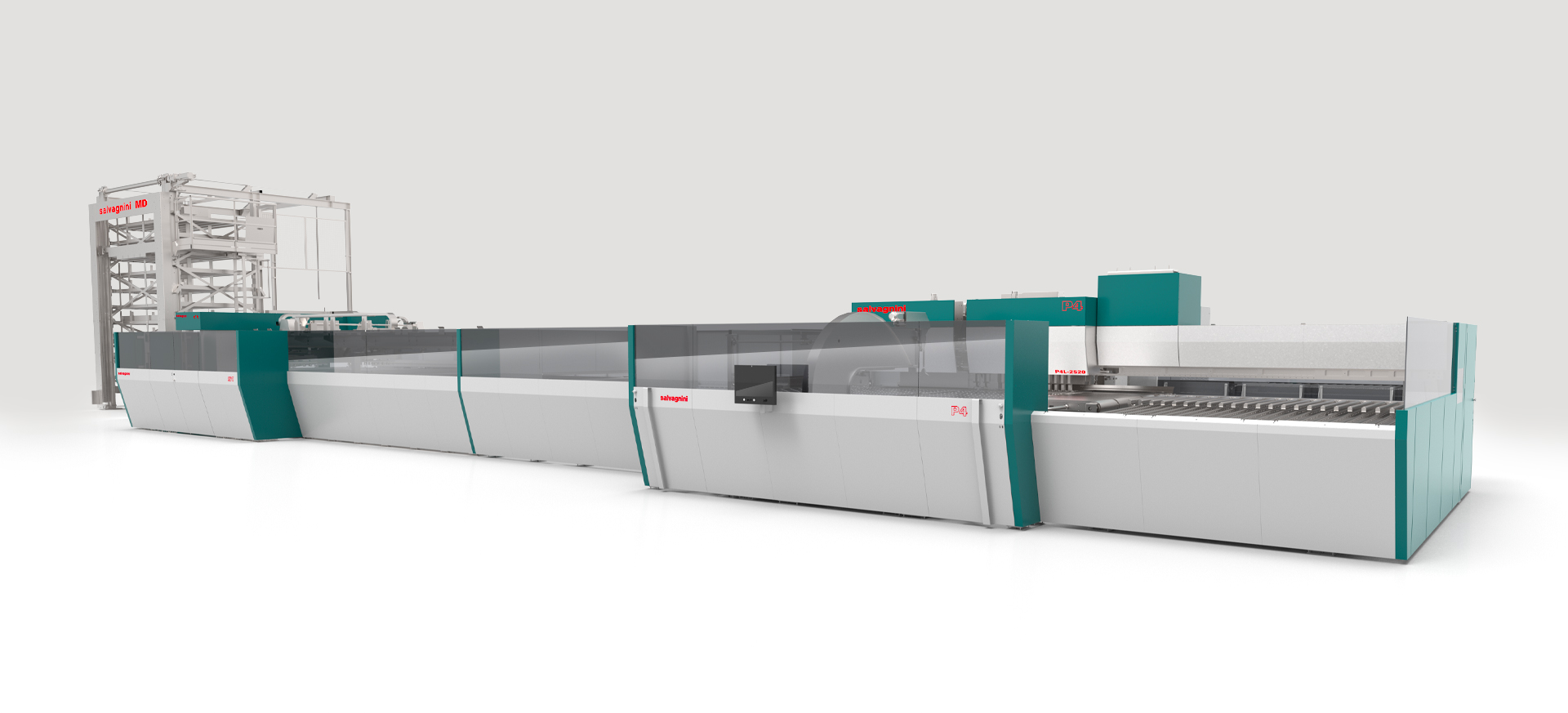

From these premises, the S1 P4 was born. It is a flexible line for the production of panels derived from sheet metal. It is presented as a modular system, consisting of a combined punching cutting center and a paneling machine. The designers were concerned, most of all, with finding a distinctive form which was capable of protecting the moving parts from any possible accidental interactions with humans, while at the same time demonstrating Salvagnini's depth in research and technology.

Perimeter protections have been studied both in the fold and in the combined use of sheet metal and Plexiglas, which (according to the principles of the golden section) respect correct proportions on the one hand, while also adhering to the possibility of making the product directly from the system itself. The casings of the S1 and P4 heads were designed with the same principle, which have the task of protecting the moving mechanical parts and their sophisticated electronic technology. Each component module of the system has been designed to be transported and set up easily. Additionally, the operator interface area is designed to improve ergonomics and overall ease of use.

Shapes, colors and graphics represent the start of capable Corporate Design, which communicates the values of the company and gives the plant (and future machines) an image of high professionalism, reliability and solidity.