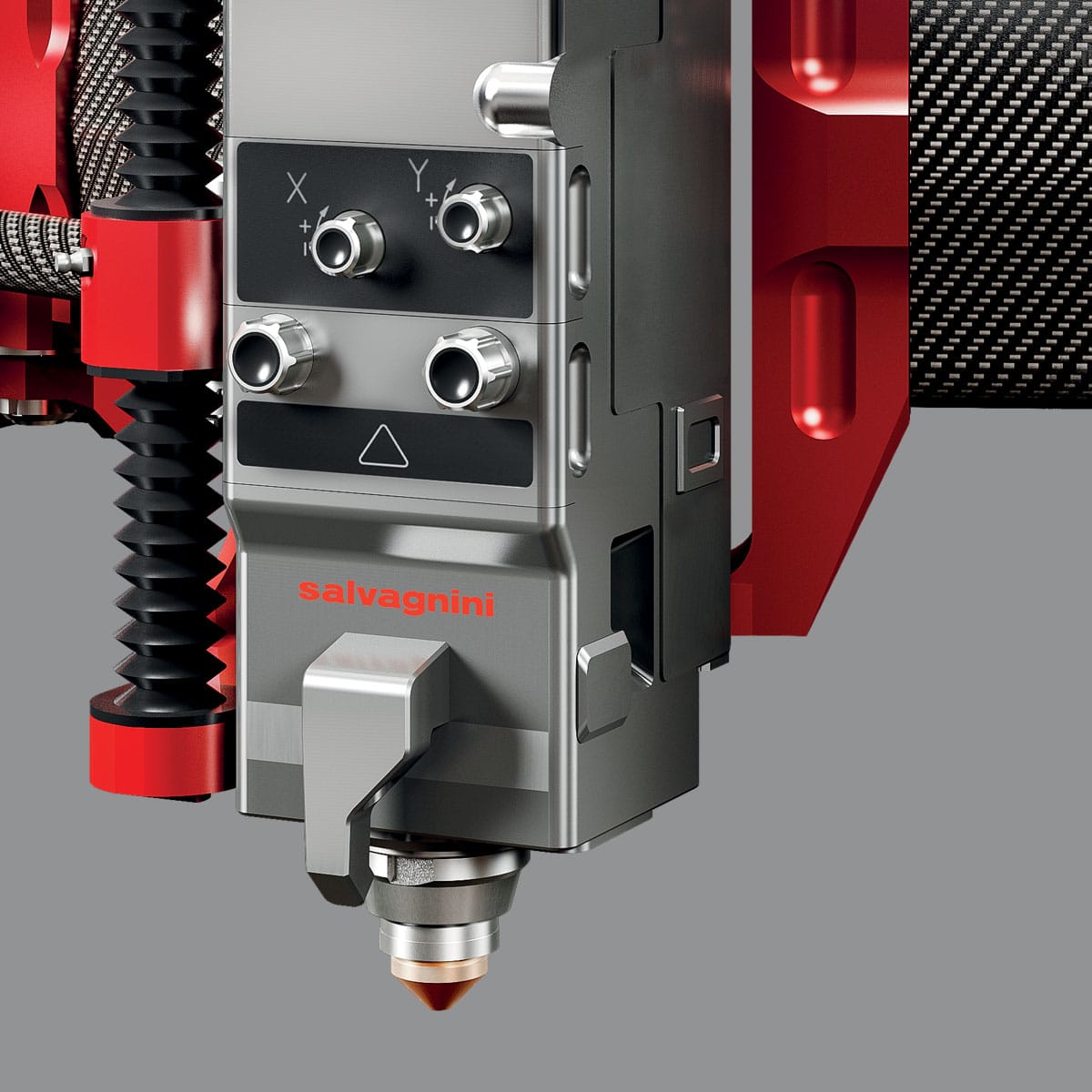

The front crown can be released to allow access to the nozzle area, while the tower can be folded down to allow easy maintenance by technicians. The new tilting tower made of steel and covered in textile material, on the other hand, combines the advantages of a tower-mounted machine with the maintainability of a mobile fan generator.

An extremely innovative concept allows TT10 to stand out from all competing products since the turbine, instead of being hinged on a technical part consisting of a compressor and electrical panel, is mounted directly on the tower, creating a whole with it. In this way costs and maintenance are optimized.

The bodywork of TT10 is made of rotational molding, contrary to what happened previously when fiberglass was used, which, due to the effect of ozone and UV rays, in a few years was damaged to the point that it was replaced, creating environmental damage, remarkable, given that fiberglass is not recyclable. The nozzle valve technology allows you to optimize energy efficiency while ensuring resource savings.