Corporate Design

Wood scanner

Corporate Design reflects the company’s Corporate Identity and can be successfully implemented, based on concepts of being unique, inspiring trust and, simultaneously, remaining current and modern over the years.

Corporate Design reflects the company’s Corporate Identity and can be successfully implemented, based on concepts of being unique, inspiring trust and, simultaneously, remaining current and modern over the years.

The choice of materials, color matching, and product graphics become important elements when completing the Microtec Corporate Design. Each product was designed and described in an application manual which allows Microtec a clear vision of elements to produce. All the criteria and principles of organization are set out in the corporate design manual, a sort of ‘bible’ for collaborators and clients.

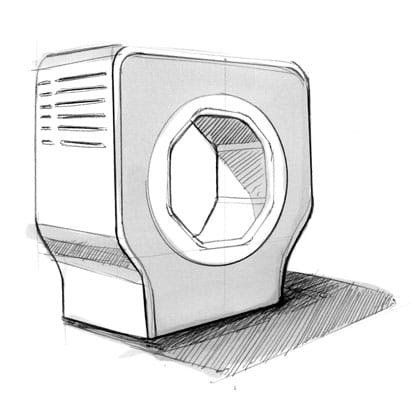

The “GoldenEye 300” series is designed as a compact and modular quality scanner system for grading wood components based on their aesthetic and structural qualities. It comes with an industrial aluminium/steel scanner body and with telescopic wing doors for full service and maintenance access. The cover of the body is made with heavy-duty steel and special multi-coated paint. All internal sensors, cameras, lasers etc. are protected against ambient conditions due to complete installation in special system boxes. The whole operation is accessed via a slim, flat screen operator terminal. All of the electronic controllers can be situated anywhere around the scanner, away from the direct machine handling area.

This series kicks off the next generation of Multi-Sensor Quality Scanners. The newly-designed scanner features several recently developed technological highlights. The scanner introduces new crometic cameras with Full HD resolution, for faster image acquisition and on-chip image processing. These new sensors are powerful enough to allow for conveying speeds of up to 100 m/min with only one camera per side, which include colour, laser scatter and 3D-scanning. Also, new X-ray technology introduces a sophisticated, single module with a fully integrated X-ray source and cooling system, which requires less power and maintenance. The new 64-bit operating system boosts faster image processing and optimization results. All sensors are protected in a dust-free environment, enabling continuous long-lasting scanning performance. The new scanner recognizes wood defects in a reliable and objective way, in order to automate, streamline and optimize manufacturing processes. The value optimization software considers customer specific grading, chopping and sorting rules.

Contact us to have more information about our projects, our ways of working and on the events that we orgaize and how we can collaborate with your business.